Electromagnetic pumps are a key enabling technology towards the development of advanced molten-salt and liquid-metal reactors, which can lead to low-waste, emission-free nuclear power plants such as small modular reactors (SMR) and micro-reactors. At Nano Nuclear Energy (NASDAQ: NNE), we are dedicated to pioneering these advancements by developing the next generation of electromagnetic pumps of the annular linear induction type. Our focus extends to both liquid metal and molten-salt reactors, encompassing a comprehensive suite of products and services related to their design and fabrication.

Nano Nuclear Energy is committed to driving innovation in the nuclear technology sector. By funding and commercializing these cutting-edge annular linear induction pumps, we are not only advancing reactor technology but also contributing to the broader goal of sustainable and efficient energy solutions. Our efforts are aimed at establishing Nano Nuclear Energy as a leader in the field, providing transformative solutions that will shape the future of nuclear power.

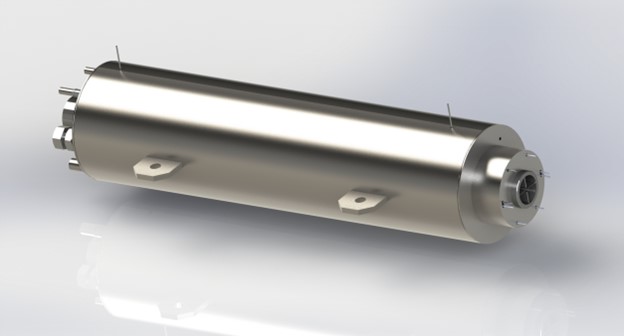

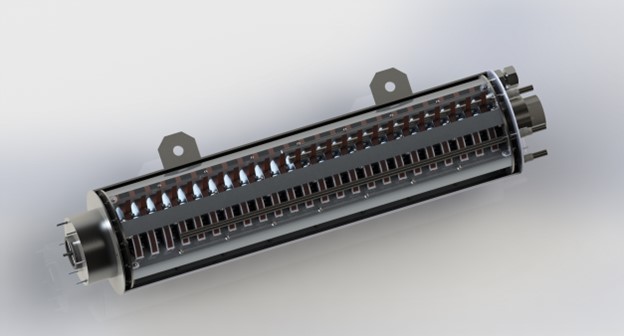

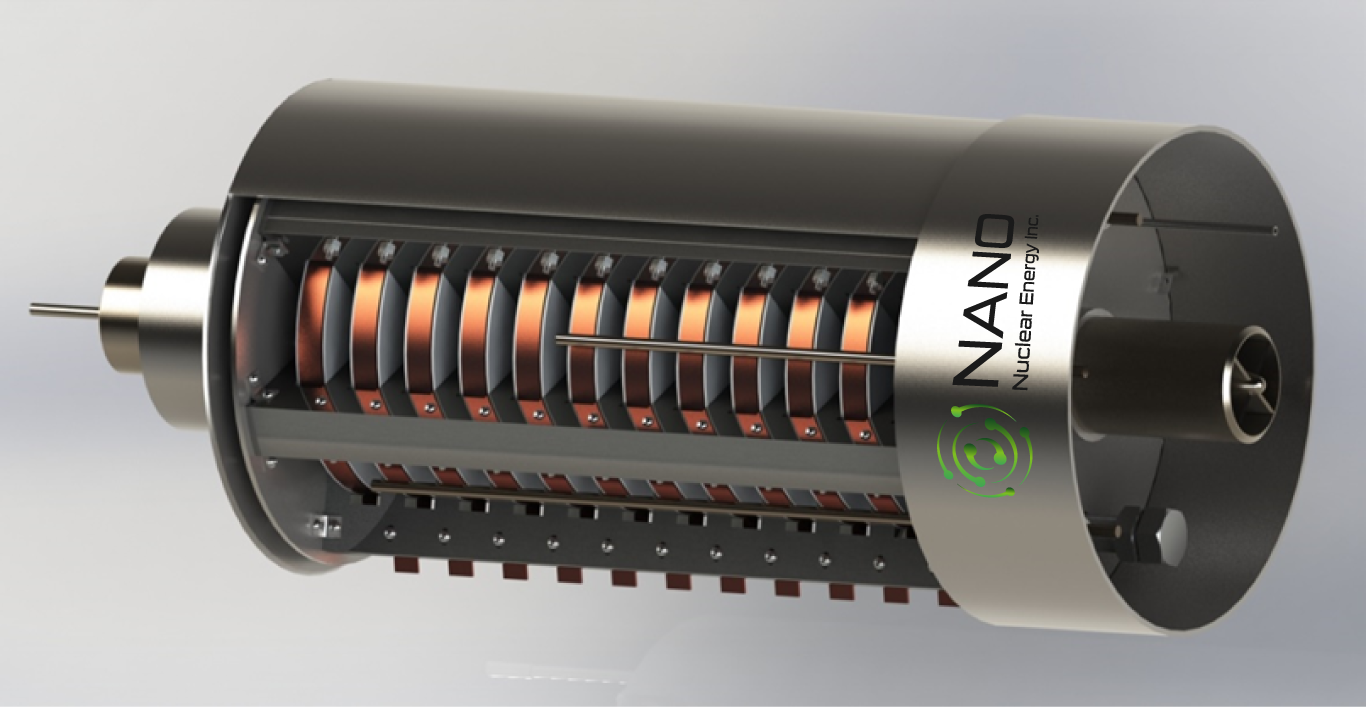

Figure 1: Annular Linear Induction Pump MR-24 external view

Near Term Commercialization & Integration

Dr. Maidana has agreed to collaborate with NANO Nuclear as a consultant on further development of the ALIP technology with a view towards achieving SBIR Phase III Award status. These efforts will build on previous Department of Energy grants for the technology, aggregating over $1.37 million in prior phases. NANO Nuclear will provide funding (estimated to be approximately $350,000) and other resources necessary for the Phase III project, and Dr. Maidana will be the Principal Investigator on this project.

The ALIP technology, which is based on electromagnetic (rather than mechanical) pumps, is a key-enabling technology to NANO Nuclear’s ODIN’, a clean energy, portable micro nuclear reactor in development. Following the previously announced completion of Idaho National Laboratory’s (INL) review of the ‘ODIN’ microreactor design in February 2024, NANO Nuclear engineers have diligently worked to identify relevant technologies to further optimize and simplify ODIN’s design. The acquired ALIP technology, to be refined during the SBIR Phase III program, is an example of this strategy in action.

Potential Reactor Clients of Novel ALIP Technology

Electromagnetic Pumps

Annular Linear Induction Pumps (ALIPs) allow the safe use of molten salts and liquid metals as a working fluid in high temperature applications in the energy, propulsion and industrial sectors. The operation at high-temperatures, in excess of 850 C (1123 K), leads to higher-efficiency energy conversion cycles. At Nano Nuclear Energy, we are designing and developing the next generation of annular linear induction pumps.

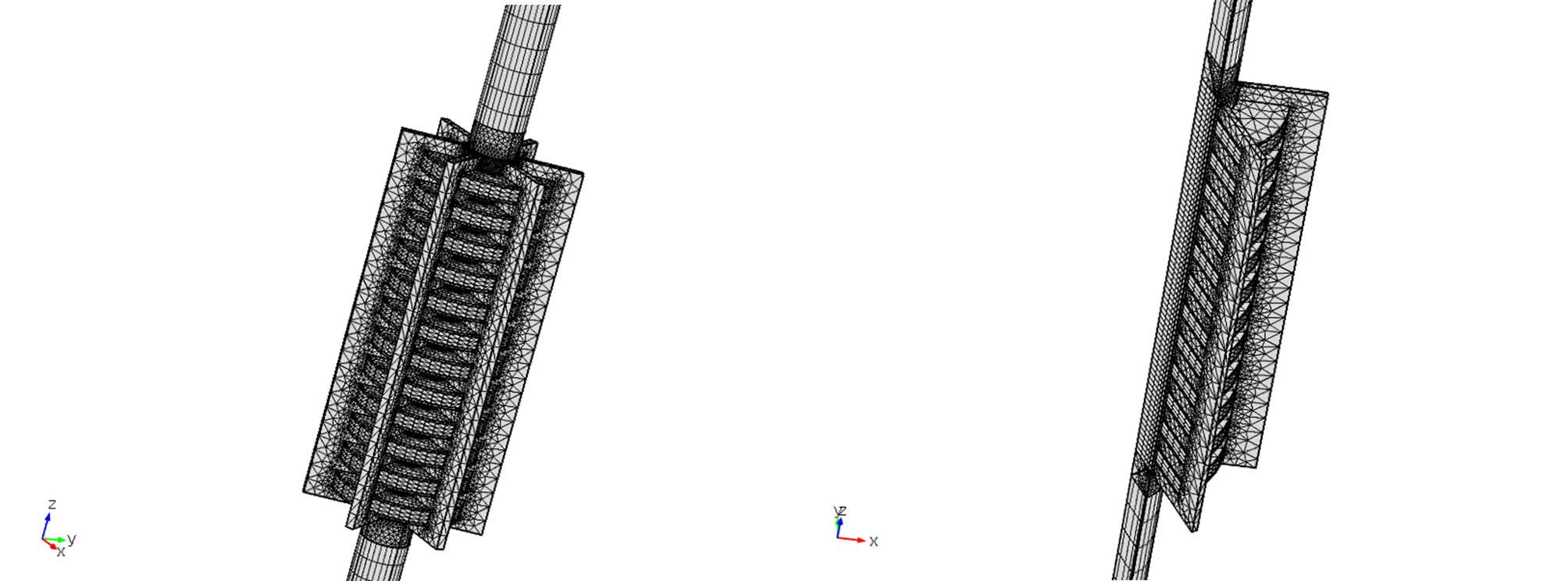

Software

We are developing software and computational tools for the design, analysis and fabrication of liquid metal and molten salts thermo-magnetic systems with emphasis in annular linear induction pumps for nuclear, space and industrial applications as well as for the study of magneto-hydrodynamics (MHD) phenomena that will enable the construction of optimized devices and components as well as new computational libraries and solvers.

CASE STUDY: The Transient Reactor Test Facility at the Idaho National Laboratory

“TREAT historically tested fuel specimens for various reactor designs, but none more than four fast breeder reactors cooled by liquid sodium. The historic irradiation vehicles used for these tests were the highly successful MK series sodium loops. One of the pivotal technologies that enabled these loops, and in turn TREAT testing of sodium cooled fuel systems, was the Annular Linear Induction Pump (ALIP). These electromagnetic pumps were ideal due to their compact form factor, high reliability due to lack of moving parts, and simple pipe like pressure boundary. Although the general geometric and performance characteristics for MK series ALIP’s are available in historic engineering documents, recovery and improvement of their design is difficult since historic electrical circuit models of their performance required empirically derived correction factors. Furthermore, reverse engineering is hampered by that fact that most of these ALIP’s were disposed as radiologic waste. For these reasons, modern tools which enable the design of ALIP’s are highly valuable to future transient experiments on liquid metal cooled fuel designs.”

Nicolas Woolstenhulme – Design and Engineering Lead for TREAT Experiments

CASE STUDY: NASA /DoE Fission Surface Power Technology Program

From 2008 to 2010, Dr. Carlos O. Maidana was heavily involved in the development of Annular Linear Induction Pumps (ALIPs) at the Idaho National Laboratory as part of a joint NASA/DoE project focused on the Fission Surface Power Technology Project – Baseline Design. This groundbreaking work laid the foundation for his extensive contributions to the field of ALIPs.

The initial ALIP designed by Dr. Maidana and his team was a pioneering effort that significantly advanced the application of electromagnetic pumps in high-temperature environments. These pumps were designed to operate at temperatures of 550°C using NaK78, making them suitable for specific energy propulsion and industrial sectors. This innovation led to more efficient energy conversion cycles and enhanced the reliability of systems due to the lack of moving parts in the pumps.

After decades without significant advancements in ALIP technology in the United States, much of the critical knowledge had been lost. Dr. Maidana’s work during this period was crucial in reviving and advancing the field. The realization that extensive expertise in ALIP design and construction had diminished over the years motivated Dr. Maidana to further pursue this technology.

Recent Developments And Future Impact

Later, at MAIDANA RESEARCH and with the support of the US Department of Energy, Dr. Maidana developed the next generation of annular linear induction pumps for high-temperature liquid metals and molten salts, with operational temperatures in excess of 1123 K. He also created the first software and computational tools worldwide for the multiphysics analysis of annular linear induction pumps. Since 2015, Dr. Maidana has secured several DoE SBIR awards, totaling $1.37 million, to support this groundbreaking work.

These tools and technologies have been instrumental in the design, analysis, and fabrication of liquid metal and molten salts thermo-magnetic systems. The advancements made possible through these SBIR-funded projects have significantly contributed to the understanding and optimization of magneto-hydrodynamics phenomena, enabling the construction of highly efficient and reliable devices and components.

Nano Nuclear Energy will fund the SBIR Phase 3 to complete the work initiated by Dr. Maidana, acquiring the technology and commercialization rights. This investment will reactivate the US capability to develop advanced thermomagnetic systems for advanced nuclear reactors, reinforcing the nation’s leadership in nuclear technology innovation.